Best Waterproof Backing Boards for Shower Installations in 2025

Bathrooms and showers are the most moisture-intensive spaces in any building. Without the right substrate protection, water can seep into wall structures, causing tile detachment, mold growth, and costly structural damage. As modern architecture moves toward greater durability and hygiene, waterproof backing boards have become an indispensable solution for wet-area installations.

In 2025, construction technology has advanced to produce waterproof backing boards that combine lightweight strength, superior waterproofing, and thermal stability. These materials are ideal for showers, steam rooms, and other high-humidity zones, ensuring long-term wall protection and improved installation efficiency.

This article introduces the best waterproof backing boards for shower installations in 2025, including their design features, installation procedures, performance testing methods, and safety operation guidelines — helping professionals and homeowners make informed choices for durable, watertight bathroom systems.

A waterproof backing board is a wall substrate specifically designed to resist water penetration in wet areas. It serves as the foundation for tiles, natural stone, or decorative wall finishes in bathrooms, showers, and wet rooms. Unlike gypsum plasterboard or plywood, waterproof backing boards maintain their strength even when exposed to water or steam for long periods.

100% water and vapor resistant

Mold and mildew resistant

Lightweight and easy to cut

High compressive and bending strength

Compatible with all standard tile adhesives

Fire-resistant and eco-friendly

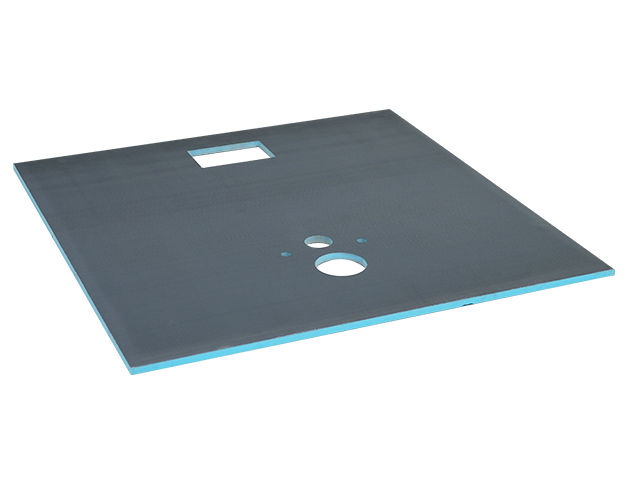

Waterproof backing boards typically consist of an extruded polystyrene (XPS) foam core reinforced with fiberglass mesh and a cementitious or polymer coating, forming a rigid and completely waterproof surface.

The 2025 generation of waterproof backing boards follows an integrated design approach that combines mechanical performance, installation convenience, and environmental responsibility.

Multilayer Structure: Each board has a waterproof core, reinforced mesh, and a treated surface to ensure adhesion and mechanical stability.

Lightweight Innovation: Reduces handling difficulty while maintaining compressive strength.

Thermal Efficiency: The XPS foam core provides insulation, improving energy efficiency in bathroom environments.

Sustainability: Many leading manufacturers now use recycled materials and VOC-free production processes to meet international green building standards.

| Parameter | Typical Specification (2025 Models) | Description |

|---|---|---|

| Material Composition | XPS foam + fiberglass mesh + cementitious coating | Waterproof and durable construction |

| Density | 30–45 kg/m³ | Lightweight yet strong |

| Water Absorption | ≤ 0.1% | Fully waterproof |

| Thermal Conductivity | ≤ 0.035 W/m·K | High insulation efficiency |

| Compressive Strength | ≥ 300 kPa | Supports tiles and wall loads |

| Flexural Strength | ≥ 200 kPa | Prevents deformation |

| Fire Rating | Class B1 / Class A | Fire-retardant protection |

| Temperature Range | -50°C to +75°C | Suitable for global climates |

| Panel Dimensions | 600×1200mm, 900×2400mm, custom sizes | Adaptable for all installations |

| Thickness Range | 6mm–50mm | From wall lining to structural support |

These figures reflect the high-quality standards of modern waterproof backing boards designed to meet both residential and commercial requirements in 2025.

Installing waterproof backing boards correctly is essential to achieving a watertight and durable shower system. The following guide outlines step-by-step installation procedures recommended by industry professionals.

Ensure the wall frame is level, solid, and free from dust or debris.

Remove any old plasterboard or damaged substrates.

Check moisture levels before installation.

Measure the wall dimensions carefully.

Cut the waterproof backing board using a utility knife or handsaw.

Smooth edges with sandpaper to ensure proper joint fitting.

Fix the boards to the wall frame using stainless steel screws and large washers or high-strength waterproof adhesive.

Keep joints tight and ensure vertical alignment.

Space fixing points approximately every 300mm for stable installation.

Apply waterproof joint tape over seams.

Use polyurethane or epoxy-based waterproof sealant to seal screw holes and edges.

Allow sealant to cure fully before tile application.

Apply thin-set tile adhesive evenly on the board surface.

Fix ceramic, porcelain, or stone tiles directly to the board.

Use waterproof grout to fill gaps and seal all joints.

After installation, allow 24–48 hours for adhesive and grout to set.

Inspect joints to ensure no gaps or leaks remain.

Following these steps guarantees a long-lasting, leak-proof shower wall system.

High-quality waterproof backing boards undergo a series of performance tests to verify structural integrity, water resistance, and thermal stability.

Water Absorption Test: Determines the board’s ability to resist moisture penetration under continuous exposure.

Compressive Strength Test: Measures load-bearing capacity when supporting tiles or fixtures.

Flexural Strength Test: Evaluates resistance to bending and cracking.

Dimensional Stability Test: Assesses expansion or contraction under temperature changes.

Vapor Permeability Test: Ensures complete moisture barrier protection.

Adhesion Test: Confirms compatibility with tile adhesives and sealants.

Aging Resistance Test: Simulates long-term humidity and heat exposure.

Each batch is inspected according to ISO and EN international standards, ensuring that all boards meet strict durability and waterproofing criteria.

Safety during installation and maintenance is essential for both professionals and DIY users.

Safety goggles to prevent debris contact.

Dust mask or respirator when cutting boards.

Gloves to avoid skin irritation from cementitious surfaces.

Protective footwear during construction.

Lift boards using two hands or a team when necessary to prevent bending.

Do not drop or drag boards on hard surfaces.

Avoid open flames or welding sparks near stored panels.

Ensure that all electrical wiring and plumbing behind the wall are installed and tested before fixing the boards.

Avoid drilling into hidden cables or water lines.

By following safety protocols, installers reduce the risk of injury and maintain the product’s integrity during the installation process.

To achieve optimal performance, several key points should be considered when working with waterproof backing boards:

Do Not Substitute Sealant: Every joint and screw hole must be properly sealed — skipping this step may lead to water ingress.

Avoid Over-Tightening Screws: Excessive pressure can damage the board’s surface layer.

Use Recommended Adhesives Only: Check compatibility with cement-based tile adhesives or polymer-bonded sealants.

Check Wall Alignment: Misaligned boards can lead to uneven tile surfaces.

Prevent Thermal Shock: Allow temperature acclimation before installation in hot or cold environments.

Store Boards Flat: Prevent warping or bending during storage.

Regular Inspection: After installation, inspect periodically to ensure joints remain sealed and stable.

Following these best practices ensures a smooth, reliable, and long-lasting waterproof wall system.

Leading manufacturers perform rigorous quality inspections at every stage — from raw material selection to final packaging.

ISO 9001: Quality Management System

ISO 14001: Environmental Management

CE Certification: Compliance with EU safety standards

VOC-Free and Formaldehyde-Free Labels: Safe for indoor use

Fire Safety Classification: Meeting B1 or A1 standards

These certifications confirm that each waterproof backing board meets international quality, environmental, and safety benchmarks.

Improved core density for higher compressive strength

Enhanced fiberglass reinforcement for stability

New hydrophobic surface coatings for better tile adhesion

Lightweight panels optimized for fast installation

100% waterproof and mold-resistant

Easy to cut, transport, and install

Excellent adhesion for tiles and sealants

Long lifespan and minimal maintenance

Suitable for both DIY and professional projects

In 2025, the latest waterproof backing boards combine engineering innovation with environmental awareness, providing both performance and sustainability.

While primarily designed for shower installations, waterproof backing boards are versatile and suitable for multiple applications:

Bathtub and Spa Surrounds

Steam Rooms and Saunas

Commercial Kitchens and Laundry Areas

Public Swimming Pool Facilities

Hospital and Laboratory Walls

Outdoor Kitchens and Garden Showers

Their resistance to moisture and chemicals makes them ideal for both residential and commercial environments.

After installation, proper cleaning and maintenance can significantly extend the service life of waterproof backing boards.

Use mild detergents or neutral cleaners for wall surfaces.

Avoid acidic or abrasive cleaning agents that can degrade grout or sealants.

Rinse with warm water and dry surfaces after cleaning.

Ensure proper bathroom ventilation to minimize condensation.

Inspect joints and corners annually for cracks or gaps.

Reapply sealant if signs of wear or peeling appear.

Avoid heavy impacts on tiled surfaces to prevent internal damage.

With regular upkeep, waterproof backing boards can provide over 20 years of stable performance.

To preserve product integrity before use, storage and transportation must follow manufacturer guidelines.

Keep panels indoors, protected from direct sunlight and rain.

Store flat and level on a clean, dry surface.

Avoid stacking heavy materials on top.

Maintain storage temperature between 5°C and 40°C.

Handle boards carefully to prevent corner or edge damage.

Use padding or protective film during long-distance shipping.

Secure stacks with straps or covers to prevent sliding during transit.

Proper handling ensures that boards arrive ready for immediate installation with no loss of structural quality.

The waterproof backing board industry continues to evolve with new nanotechnology coatings, recycled materials, and modular installation systems. In 2025 and beyond, manufacturers are focusing on:

Eco-certified materials with low carbon footprints

Smart moisture-detection layers for early leak alerts

Pre-finished decorative waterproof panels for faster installation

Integrated insulation and acoustic properties

These advancements align with global trends in sustainable construction, energy efficiency, and smart building solutions.

The Best Waterproof Backing Boards for Shower Installations in 2025 deliver unparalleled protection, efficiency, and longevity for modern bathrooms. Their superior waterproofing, ease of installation, and tested performance make them the ultimate choice for professionals and homeowners seeking permanent solutions against moisture damage.

By following correct installation steps, adhering to safety practices, and maintaining regular inspection, builders can ensure decades of structural integrity and aesthetic beauty. Waterproof backing boards are not just a construction product — they are a foundation of modern, durable, and hygienic bathroom design.

Leave your email address and we will send you the latest product information

Langfang Huaneng Building Materials Co., Ltd. was established on October 24, 1996. It is a subsidiary of Huaneng Zhongtian Energy Conservation Technology Group Co., Ltd.

Copyright © 2025 Langfang Huaneng Building Materials Co., Ltd. All rights reserved

Este sitio web utiliza cookies para garantizar que obtenga la mejor experiencia en nuestro sitio web.

Comentario

(0)